Abstract

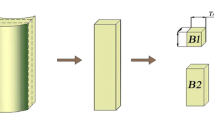

Bamboo pith ring (BPR) is regarded as a particular tissue affecting bamboo processing and is usually discarded, resulting in waste and low utilization of bamboo. To improve the utilization of bamboo and make full use of BPR, the fundamental properties, including morphology, chemical properties, and mechanical properties of BPR by confocal laser-scanning microscope, SEM, IR-image, and nanoindentation, were investigated in this study. On the macroscale, the stone cells in BPR are round or square and closely arranged, and the average thickness of BPR is 404.6 μm. On the cell scale, with the increase in distance from the pith cavity, stone cells show different shapes and sizes. On the cell wall scale, the stone cell in BPR show a multi-layer structure with alternating thick and thin walls, and there are dense pits on the wall layer. Stone cell is mainly composed of cellulose, hemicellulose, and lignin, and hemicellulose and lignin contents are higher than parenchyma cell. The elastic modulus and hardness of the stone cell wall were 6.98 GPa and 491.8 MPa, respectively. Studying BPR morphology, chemical, and mechanical properties are expected to lay a foundation for, among others, bamboo gluing, mechanics research, and drying cracking.

Similar content being viewed by others

References

Banik N, Dey V, Sastry GRK (2017) An overview of lignin & hemicellulose effect upon biodegradable bamboo fiber composites due to moisture. Mater Today: Proc 4:3222–3232

Chen L, Huang B, Wang X et al (2022) Study on gluing characteristics of bamboo pith ring. Ind Crops Prod 178:114624

Deng J, Li H, Wang G et al (2015) Effect of removing extent of bamboo green on physical and mechanical properties of laminated bamboo-bundle veneer lumber (BLVL). Eur J Wood Prod 73:499–506

Fang C-H, Jiang Z-H, Sun Z-J et al (2018) An overview on bamboo culm flattening. Constr Build Mater 171:65–74

Grosser D, Liese W (1971) On the anatomy of Asian bamboos, with special reference to their vascular bundles. Wood Sci Technol 5:290–312

He Q, Zhan T, Zhang H et al (2019) Robust and durable bonding performance of bamboo induced by high voltage electrostatic field treatment. Ind Crops Prod 137:149–156

Huang X, Huang J, Hse C et al (2019) Study on the mold-resistant properties of moso bamboo treated with starch amylase. J for Eng 4:60–65

Lian C, Liu R, **ufang C et al (2019) Characterization of the pits in parenchyma cells of the Moso bamboo [Phyllostachys edulis (Carr.) J. Houz.] culm. Holzforschung 73:629–636

Lian C, Liu R, Zhang S et al (2020a) Ultrastructure of parenchyma cell wall in bamboo (Phyllostachys edulis) culms. Cellulose 27(13):7321–7329

Lian C, Zhang S, Liu X et al (2020b) Uncovering the ultrastructure of ramiform pits in the parenchyma cells of bamboo [Phyllostachys edulis (Carr.) J. Houz.]. Holzforschung 74:321–331

Liese W, Köhl M (2015) Bamboo: the plant and its uses. Springer 8:35. https://doi.org/10.1007/978-3-319-14133-6

Liese W, Schmitt U (2006) Development and structure of the terminal layer in bamboo culms. Wood Sci Technol 40:4–15

Liese W, Tang TKH (2015) Preservation and drying of bamboo. Springer pp 257–297. https://doi.org/10.1007/978-3-319-14133-6_9

Liu W, Hui C, Wang F, et al (2018) Review of the resources and utilization of bamboo in China. Bamboo-Current and Future Prospects pp 133–142

Lou Z, Yuan T, Wang Q et al (2021) Fabrication of crack-free flattened bamboo and its macro-/micromorphological and mechanical properties. J Renew Mater 9(5):959

Özparpucu M, Gierlinger N, Cesarino I et al (2019) Significant influence of lignin on axial elastic modulus of poplar wood at low microfibril angles under wet conditions. J Exp Bot 70:4039–4047

Qisheng Z, Shenxue J, Yongyu T (2002) Industrial utilization on bamboo. International network for bamboo and rattan Bei**g, China

Sharma B, Gatóo A, Ramage MH (2015) Effect of processing methods on the mechanical properties of engineered bamboo. Constr Build Mater 83:95–101

Singh A, Dawson B, Rickard C et al (2008) Light, confocal and scanning electron microscopy of wood-adhesive interface. Microsc Anal 22:5–8

Su N, Fang C, Yu Z et al (2021) Effects of rosin treatment on hygroscopicity, dimensional stability, and pore structure of round bamboo culm. Constr Build Mater 287:123037

van Dam JE, Elbersen HW, Montaño CMD (2018) Bamboo production for industrial utilization. Perennial grasses for bioenergy and bioproducts, pp 175–216

Wang X, Zhang S, Chen L et al (2022) Effects of pith ring on the hygroscopicity and dimensional stability of bamboo. Ind Crops Prod 184:115027

Wei F, Jianqin H, Min L et al (1998) Comparative anatomy on seventeen species of tufted bamboos. J Zhejiang Agric for Univ 15:225–231

**ong W, Qiao S, Li Y (1980) Moso bamboo (Phyllostachys pubescens Mazel ex H. de Lehaie) Anatomical structure of culm. J Integr Plant Biol 4:343–348

Yu Y, Liu R, Huang Y et al (2017) Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr Build Mater 157:1032–1039

Yu Y, Tian G, Wang H et al (2011) Mechanical characterization of single bamboo fibers with nanoindentation and microtensile technique. Holzforschung 65:113–119

Yuan J, Fang C, Chen Q, Fei B (2021) Observing bamboo dimensional change caused by humidity. Constr Build Mater 309:124988

Acknowledgements

The authors gratefully acknowledge financial support from the Foundation of the International Center for Bamboo and Rattan (1632019002), and National Natural Science Foundation of China (Grant number 32230072).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Deceased: Benhua Fei.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, L., Wang, X., Huang, B. et al. Observation of the fundamental properties of bamboo pith ring. Wood Sci Technol 58, 797–810 (2024). https://doi.org/10.1007/s00226-023-01523-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-023-01523-0