Abstract

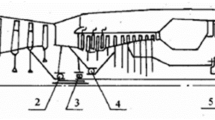

The high-pressure rotor of aero-engine is assembled by numerous bolts under high manufacture precision. The connected structure is subjected to both axial force and transverse vibration during service, which may result in individual bolt loosen. In this study, the influence of bolt missing on the dynamic characteristics is analyzed by numerical simulation. A test rig capable of impact and frequency swee** experiment under axial tension was constructed. The vibration response features in the simulation were then extracted. The loss function of the mean absolute error and the decision method of extreme gradient boosting were used to predict the bolt missing position. The results show that the proposed model can reach a prediction precision of more than 90%. Moreover, the coefficient of determination evaluation index of the prediction effect reaches 0.9, which is significantly higher than those of other conventional models such as multivariate linear regression and multivariate adaptive regression spliness.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to their containing information that could compromise the privacy of research participant.

References

Antoni N (2013) Contact separation and failure analysis of a rotating thermo-elastoplastic shrink-fit assembly[J]. Appl Math Model 37:2352–2363

Fu C, Zhu WD, Zheng ZL, Sun CZ, Yang YF, Lu K* (2022) Nonlinear responses of a dual-rotor system with rub-impact fault subject to interval uncertain parameters. Mechanical Systems and Signal Processing 170:108827

Whitney DE, Gilbert OL, Jastrzebski M (1994) Representation of geometric variations using matrix transforms for statistical tolerance analysis in assemblies. Res Eng Des 6(4):191–210

**aokai Mu, Wang Y, Yuan Bo et al (2021) A New assembly precision prediction method of aeroengine high-pressure rotor system considering manufacturing error and deformation of parts[J]. J Manuf Syst 61:112–124

Ding SY, Zheng XH (2021) Precision control of rotors assembly based on improved Jacobian-Torsor theory[J]. Acta Aeronautica et Astronautica Sinica 42:424670

Liu Y, Zhang M, Sun C et al (2019) A method to minimize stage-by-stage initial unbalance in the aero engine assembly of multistage rotors[J]. Aerosp Sci Technol 85:270–276

Chuanzhi SUN, Zewei Liu, Yongmeng LIU, et al 2019 An Adjustment Method of Geometry and Mass Centers for Precision Rotors Assembly[J].IEEE ACCESS 2955124

Youlin BAO, Lixin LI, Peng CAO et al (2021) Optimization of rotor assembly process of rotor initial unbalance of an aeroengine gas generator [J]. Trans Nan**g Univ Aeronaut Astronaut 38(1):132–139

Nassar SA, Veeram AB (2005) Ultrasonic control of fastener tightening using varying wave speed. J Pressure Vessel Technol 128:427–432

Amerini F, Meo M (2011) Structural health monitoring of bolted joints using linear and nonlinear acoustic/ultrasound methods[J]. Struct Health Monit 10(6):659–672

Eissa M, Saeed NA (2016) Nonlinear vibration control of a horizontally supported Jeffcott-rotor system[J]. J Vib Control 24(24):5898–5921

Liu S, Ma Y, Zhang D et al (2012) Studies on dynamic characteristics of the joint in the aero-engine rotor system[J]. Eng Fail Anal 29(5):120–136

Sun W, Li T, Yang D et al (2020) Dynamic investigation of aeroengine high pressure rotor system considering assembly characteristics of bolted joints[J]. Eng Fail Anal 112:104510

Hernández S, Menga E, Moledo S, Romera LE, Baldomir A, López C, Montoya MC (2017) Optimization approach for identification of dynamic parameters of localized joints of aircraft assembled structures, Aerosp. Sci Technol 69:538–549

Lia Y, Luoa Z, Liu J et al (2021) Dynamic modeling and stability analysis of a rotor-bearing system with bolted-disk joint. Mech Syst Signal Process 158:107778

Beaudoin M-A, Behdinan K (2019) Analytical lump model for the nonlinear dynamic response of bolted flanges in aero-engine casings. Mech Syst Signal Process 115:14–28

**chao Yu, Li L, Chen G, Yang M (2021) Dynamic modelling and vibration characteristics analysis for the bolted joint with spigot in the rotor system. Appl Math Model 94:306–331

Breiman (1990) Classification and Regression tree Models. London: Chapman & Hall

Chakraborty D, Elzarka H (2019) Early detection of faults in HVAC systems using an XGBoost model with a dynamic threshold. Energy Build 185:326–344

Chen T, Guestrin C (2016) Xgboost: a scalable tree boosting system. In: Proceedings of the 22nd ACM SIGKDD international conference on knowledge discovery and data mining. ACM, New York, pp 785–794

Trizoglou P, Liu X, Lin Zi (2021) Fault detection by an ensemble framework of Extreme Gradient Boosting (XGBoost) in the operation of offshore wind turbines. Renewable Energy 179:945–962

Chen K, Chen H, Liu L et al (2019) Prediction of weld bead geometry of MAG welding based on XGBoost algorithm. Int J Adv Manuf Technol 101:2283–2295

Zhang Z, Huang Y, Qin R et al (2021) XGBoost-based on-line prediction of seam tensile strength for Al-Li alloy in laser welding: Experiment study and modelling. J Manuf Proc 64:30–44

Lin J, Qi C, Wan H et al (2021) Prediction of Cross-Tension Strength of Self-Piercing Riveted Joints Using Finite Element Simulation and XGBoost Algorithm. Chin J Mech Eng 34:36

Phan QT, Wu YK, Phan QD (2021) A Hybrid Wind Power Forecasting Model with XGBoost, Data Preprocessing Considering Different NWPs. Appl Energy 11:1100

Patnaik B, Mishra M, Bansal RC et al (2021) MODWT-XGBoost based smart energy solution for fault detection and classification in a smart microgrid. Appl Energy 285:116457

Choi D-K (2019) Data-Driven Materials Modeling with XGBoost Algorithm and Statistical Inference Analysis for Prediction of Fatigue Strength of Steels. Int J Precis Eng Manuf 20:129–138

Yao X, Wang J (2017) Effects of load and structure parameters of aero-engine bolted joints on joint stiffness[J]. J Propuls Technol 38(2):424–433

Jofriet JC, Sze Y, Thompson JC (1981) The interface boundary conditions for bolted flanged connections[J]. J Pressure Vessel Technol 103(3):240–245

Johnson KL (1985) Contact mechanics[J], J. Tribol 108(4):464

Shehadeh A, Alshboul O, Mamlook REA et al (2021) Machine learning models for predicting the residual value of heavy construction equipment: An evaluation of modified decision tree, LightGBM, and XGBoost regression[J]. Autom Constr 129:103827

Funding

This research was sponsored by the National Natural Science Foundation of China (51905334), Shanghai Sailing Program (19YF1452400 and 19YF1418600).

Author information

Authors and Affiliations

Contributions

Conceptualization, C.Y. and HS.C.; methodology, C.Y.; validation, ZX.M. and JY.F..; formal analysis, ZL.Z.; investigation, C.Y.;. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yue, C., Chi, H., Fan, J. et al. Prediction of bolt missing fault for multistage rotor by experimental test and analysis. Int J Adv Manuf Technol 124, 4551–4562 (2023). https://doi.org/10.1007/s00170-022-10356-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10356-3