Abstract

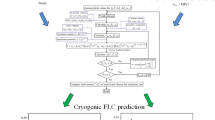

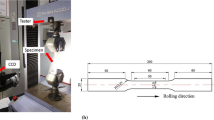

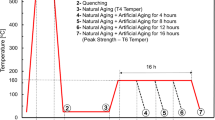

This study aims to investigate the formability of the AA2198-T3 Al-Li alloy in hydro-mechanical deep drawing (HMDD), through experimentation and finite element simulation. The effects of the most critical factors were studied: die cavity pressure and forming temperature; the forming temperature is selected at 298K and 423K. The Gurson−Tvergaard−Needleman model (GTN model) was employed to analyze the formability of AA2198-T3 Al-Li alloy and predict the fracture in the hydroforming of a cylindrical part. Both the numerical and experimental results showed that the increase of the pressure inside the liquid chamber, within a certain range, contributes to improve the formability of the alloy. Increasing the temperature would reduce the required pressure for sheet hydroforming. Notably, the appropriate chamber pressure was beneficial to form good quality parts with a relatively uniform wall thickness. By analyzing the fracture morphologies, the brittle fracture of AA2198-T3 plays a main role at room temperature, but the ductile fracture was shown at the elevated temperature.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request. The software application of this study can be obtained from the corresponding author upon reasonable request.

References

Abd El-Aty A, Xu Y, Guo XZ, Zhang S, Chen D (2017) Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. Journal of Advanced Research

Rioja RJ, Liu J (2012) The evolution of Al-Li base products for aerospace and space applications. Metall. Trans. A 43(9):3325–3337

Zhang SF, Zeng WD, Yang WH, Shi CL, Wang HJ (2014) Ageing response of a Al–Cu–Li 2198 alloy. Mater. Des 63(2):368–374

Alexopoulos ND, Migklis E, Stylianos A, Myriounis DP (2013) Fatigue behavior of the aeronautical Al–Li (2198) aluminum alloy under constant amplitude loading. Int. J. Fatigue 56(11):95–105

Lequeu P, Lassince P, Warner T (2007) Aluminum alloy development for the Airbus A380 - part 2. Adv. Mater. Process 165(7):41–44

Decreus B, Deschamps A, Geuser FD et al (2013) The influence of Cu/Li ratio on precipitation in Al–Cu–Li–x alloys. Acta Mater 61(6):2207–2218

Steglich D, Wafai H, Brocks W (2010) Anisotropic deformation and damage in aluminum 2198 T8 sheets. Int. J. Damage Mech 19(2):131–152

Palumbo G, Piglionico V, Piccininni A et al (2015) Evaluation of the optimal working conditions for the warm sheet HydroForming taking into account the yielding condition. Mater. Des 91:411–423

Prete AD, Papadia G, Vitis AD, Primo T (2011) Finite Element Simulations for Sheet Warm Hydroforming. AIP Conf. Proc 1353:313–318

Abd El-Aty A, Xu Y, Zhang SH et al (2017) Experimental investigation of tensile properties and anisotropy of 1420, 8090 and 2060 Al-Li alloys sheet undergoing different strain rates and fibre orientation: a comparative study. Procedia Eng 207:13–18

Halkaci HS, Turkoz M, Dilmec M (2013) Enhancing formability in hydromechanical deep drawing process adding a shallow drawbead to the blank holder. J. Mater. Process. Technol 214(8):1638–1646

Kang BS, Ku TW (2011) Experimental study on multi-stage deep drawing for rectangular cup with high aspect ratio. Int. J. Adv. Manuf. Technol 53(1):131–143

Toros S, Ozturk F, Kacar I (2008) Review of warm forming of aluminum–magnesium alloys. J. Mater. Process. Technol 207(1-3):1–12

Hama T, Kitajima T, Nishimura Y, Fujimoto H, Takuda H (2012) Effect of outflow volume of pressure medium on liquid-lubrication effect during sheet hydroforming. Mater. Trans 53(5):826–832

Wang YM, Lang LH, **e YS (2012) Numerical and experimental investigation into the aluminum alloy irregular box sheet hydroforming process. Adv. Mater. Res 602-604:1846–1849

Koç M, Mahabunphachai S, Carsley JE (2010) Numerical and experimental investigations on deformation behavior of aluminum 5754 sheet alloy under warm hydroforming conditions. Numiform 1252(1):107–115

Hosseinpour M, Gorji A, Bakhshi M (2015) On the experimental and numerical study of formability of aluminum sheet in warm hydroforming process. Modares Mechanical Engineering 7(3):238–253

Ling J, Guo XZ, Li HG (2015) Constitutive equation and numerical simulation of hydro-mechanical deep drawing of 2198 Al-Li alloy. Journal of Plasticity Engineering 22(2):78–83

Ludwik P (1909) Elemente der technologischen Mechanik[M]// Elemente der Technologischen Mechanik. Springer Berlin Heidelberg

Alegre JM, Cuesta II, Bravo PM (2011) Implementation of the GTN damage model to simulate the small punch test on pre-cracked specimens. Procedia Eng 10(1):1007–1016

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: Part I-yield criteria and flow rules for porous media. J. Eng. Mater. Technol 99(1):297–300

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32(1):157–169

Benseddiq N, Imad A (2008) A ductile fracture analysis using a local damage model. Int. J. Press. Vessel. Pip 85(4):219–227

Fratini L, Lombardo A, Micari F (1996) Material characterization for the prediction of ductile fracture occurrence: An inverse approach. J. Mater. Process. Technol 60(1-4):311–316

Nègre P, Steglich D, Brocks W (2004) Crack extension in aluminium welds: a numerical approach using the Gurson-Tvergaard-Needleman model. Eng. Fract. Mech 71(16-17):2365–2383

Kami A, Dariani BM, Vanini AS, Comsa DS, Banabic D (2014) Numerical determination of the forming limit curves of anisotropic sheet metals using GTN damage model. J. Mater. Process. Technol 216:472–483

Funding

This work is funded by the Bureau of international cooperation of the Chinese Academy of Sciences (174321KYSB20150020), the National Natural Science Foundation of China (Grant No. 51605310), Jiangsu Province Science and Technology Program (Grant No. BE2016156), Shenyang Science and Technology Program (17-32-6-00), the Research Project of State Key Laboratory of Mechanical System and Vibration (MSV201708), and the Research Fund of Nan**g University of Aeronautics and Astronautics (No. YAH17019).

Author information

Authors and Affiliations

Contributions

Hui Wang put forward research ideas and design research schemes. Sijia Cheng is responsible for collecting, collating, and analyzing data. Zhuang Ye is responsible for revision, typesetting, and final revision. Tianli Wu, Kai **, and Xunzhong Guo are in charge of conducting experiments.

Corresponding author

Ethics declarations

Ethics approval

No ethical approval is required for this article.

Competing interests

The authors declare no competing interests

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, H., Cheng, S., Ye, Z. et al. Evaluation of the formability of AA2198-T3 Al-Li alloy in warm sheet hydroforming. Int J Adv Manuf Technol 118, 405–416 (2022). https://doi.org/10.1007/s00170-021-07961-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07961-z