Abstract

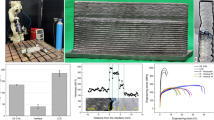

Bimetal composites have wide applications due to their excellent overall performance and relatively low cost. In this study, the formability of stainless/carbon steel bimetal medium-thick composite in the stam** process without blank holder was investigated by finite element (FE) simulations and experiments. Uniaxial tensile tests on substrate metal (carbon steel) and clad metal (stainless steel) were first conducted, respectively, in order to obtain the material properties of each metal layer required in the FE simulation. Processing variables, including the layer stacking sequence, relative thickness ratios of two layers and friction conditions, were considered, and their effects on the magnitude of press load and distributions of thickness strain for predicting the high-risk region of necking during stam** were discussed. Experimental tests were carried out to verify the simulation results. It is indicated that simulation results can be used as an evaluation indicator to ensure the bimetal medium-thick composite can be safely formed.

Similar content being viewed by others

References

Yilamu K, Hino R, Hamasaki H, Yoshida F (2010) Air bending and springback of stainless steel clad aluminum sheet. J Mater Process Technol 210:272–278. https://doi.org/10.1016/j.jmatprotec.2009.09.010

Bai Q-L, Zhang L-J, **e M-X, Yang H-X, Zhang J-X (2017) An investigation into the inhomogeneity of the microstructure and mechanical properties of explosive welded H62-brass/Q235B-steel clad plates. Int J Adv Manuf Technol 90:1351–1363. https://doi.org/10.1007/s00170-016-9440-4

Al-Ghamdi KA, Hussain G (2016) On the comparison of formability of roll-bonded steel-cu composite sheet metal in incremental forming and stam** processes. Int J Adv Manuf Technol 87:267–278. https://doi.org/10.1007/s00170-016-8488-5

Deqing W, Ziyuan S, Ruobin Q (2007) Cladding of stainless steel on aluminum and carbon steel by interlayer diffusion bonding. Scr Mater 56:369–372. https://doi.org/10.1016/j.scriptamat.2006.11.003

Xu J, Gao X, Jiang Z, Wei D, Jiao S (2016) Microstructure and hot deformation behaviour of high-carbon steel/low-carbon steel bimetal prepared by centrifugal composite casting. Int J Adv Manuf Technol 86:817–827. https://doi.org/10.1007/s00170-015-8232-6

Li Z, Zhao J, Jia F, Zhang Q, Liang X, Jiao S, Jiang Z (2018) Analysis of bending characteristics of bimetal steel composite. Int J Mech Sci 148:272–283. https://doi.org/10.1016/j.ijmecsci.2018.08.032

Oya T, Tiesler N, Kawanishi S, Yanagimoto J, Koseki T (2010) Experimental and numerical analysis of multilayered steel sheets upon bending. J Mater Process Technol 210:1926–1933. https://doi.org/10.1016/j.jmatprotec.2010.07.003

Khodadad Motarjemi A, Koçak M, Ventzke V (2002) Mechanical and fracture characterization of a bi-material steel plate. Int J Press Vessel Pip 79:181–191. https://doi.org/10.1016/S0308-0161(02)00012-1

Bagherzadeh S, Mollaei-Dariani B, Malekzadeh K (2012) Theoretical study on hydro-mechanical deep drawing process of bimetallic sheets and experimental observations. J Mater Process Technol 212:1840–1849. https://doi.org/10.1016/j.jmatprotec.2012.04.002

Liu BX, Yin FX, Dai XL, He JN, Fang W, Chen CX, Dong YC (2017) The tensile behaviors and fracture characteristics of stainless steel clad plates with different interfacial status. Mater Sci Eng A 679:172–182. https://doi.org/10.1016/j.msea.2016.10.033

Parsa MH, Mohammadi SV, Aghchai AJ (2014) Al3105/polypropylene/Al3105 laminates springback in V-die bending. Int J Adv Manuf Technol 75:849–860. https://doi.org/10.1007/s00170-014-6173-0

Liu W, Sun X, Ruokolainen R, Gayden X (2007) Investigation of forming performance of laminated steel sheets using finite element analyses. AIP Conf Proc 908:895–900. https://doi.org/10.1063/1.2740924

Mori T, Kurimoto S (1996) Press-formability of stainless steel and aluminum clad sheet. J Mater Process Technol 56:242–253. https://doi.org/10.1016/0924-0136(95)01838-7

Kapie Ski S (1996) Analytical and experimental analysis of deep drawing process for bimetal elements. J Mater Process Technol 60:197–200. https://doi.org/10.1016/0924-0136(96)02328-X

Takuda H, Fujimoto H, Hatta N (1998) Formabilities of steel/aluminium alloy laminated composite sheets. J Mater Sci 33:91–97. https://doi.org/10.1023/A:1004393529187

Takuda H, Hatta N (1998) Numerical analysis of the formability of an aluminum 2024 alloy sheet and its laminates with steel sheets. Metall Mater Trans A 29:2829–2834. https://doi.org/10.1007/s11661-998-0323-7

Takuda H, Mori K, Fujimoto H, Hatta N (1996) Prediction of forming limit in deep drawing of Fe/Al laminated composite sheets using ductile fracture criterion. J Mater Process Technol 60:291–296. https://doi.org/10.1016/0924-0136(96)02344-8

Yoshida F, Hino R (1997) Forming limit of stainless steel-clad aluminium sheets under plane stress condition. J Mater Process Technol 63:66–71. https://doi.org/10.1016/S0924-0136(96)02601-5

Parsaa Habibi Mohammad YK, Norio T (2001) Redrawing analysis of aluminum–stainless-steel laminated sheet using FEM simulations and experiments. Int J Mech Sci 43:2331–2347

Huang Y-M (2007) An elasto-plastic finite element analysis of the sheet metal stretch flanging process. Int J Adv Manuf Technol 34:641–648. https://doi.org/10.1007/s00170-007-0958-3

Morovvati MR, Fatemi A, Sadighi M (2011) Experimental and finite element investigation on wrinkling of circular single layer and two-layer sheet metals in deep drawing process. Int J Adv Manuf Technol 54:113–121. https://doi.org/10.1007/s00170-010-2931-9

Li H, Chen J, Yang J (2013) Experiment and numerical simulation on delamination during the laminated steel sheet forming processes. Int J Adv Manuf Technol 68:641–649. https://doi.org/10.1007/s00170-013-4785-4

Tseng H-C, Hung C, Huang C-C (2010) An analysis of the formability of aluminum/copper clad metals with different thicknesses by the finite element method and experiment. Int J Adv Manuf Technol 49:1029–1036. https://doi.org/10.1007/s00170-009-2446-4

Tseng H-C, Hung J-C, Hung C, Lee M-F (2011) Experimental and numerical analysis of titanium/aluminum clad metal sheets in sheet hydroforming. Int J Adv Manuf Technol 54:93–111. https://doi.org/10.1007/s00170-010-2911-0

Atrian A, Fereshteh-Saniee F (2013) Deep drawing process of steel/brass laminated sheets. Compos Part B 47:75–81. https://doi.org/10.1016/j.compositesb.2012.10.023

Dehghani F, Salimi M (2016) Analytical and experimental analysis of the formability of copper-stainless-steel 304L clad metal sheets in deep drawing. Int J Adv Manuf Technol 82:163–177. https://doi.org/10.1007/s00170-015-7359-9

Jalali Aghchai A, Shakeri M, Mollaei Dariani B (2013) Influences of material properties of components on formability of two-layer metallic sheets. Int J Adv Manuf Technol 66:809–823. https://doi.org/10.1007/s00170-012-4368-9

Aghchai AJ, Shakeri M, Mollaei-Dariani B (2008) Theoretical and experimental formability study of two-layer metallic sheet (Al1100/St12). Proc Inst Mech Eng B 222:1131–1138. https://doi.org/10.1243/09544054JEM1140

Wu J, Zou F (2016) Deep drawing failure map of a coated metal sheet based on the process parameters. J Fail Anal Prev 16:361–368. https://doi.org/10.1007/s11668-016-0097-y

Wu J, Ma Z, Zhou Y, Lu C (2013) Prediction of failure modes during deep drawing of metal sheets with nickel coating. J Mater Sci Technol 29:1059–1066. https://doi.org/10.1016/j.jmst.2013.08.001

Afshin E, Kadkhodayan M (2015) An experimental investigation into the warm deep-drawing process on laminated sheets under various grain sizes. Mater Des 87:25–35. https://doi.org/10.1016/j.matdes.2015.07.061

Karajibani E, Hashemi R, Sedighi M (2015) Determination of forming limit curve in two-layer metallic sheets using the finite element simulation. Proc Inst Mech Eng L 230:1018–1029. https://doi.org/10.1177/1464420715593565

Karajibani E, Fazli A, Hashemi R (2015) Numerical and experimental study of formability in deep drawing of two-layer metallic sheets. Int J Adv Manuf Technol 80:113–121. https://doi.org/10.1007/s00170-015-6978-5

Hashemi R, Karajibani E (2016) Forming limit diagram of Al-Cu two-layer metallic sheets considering the Marciniak and Kuczynski theory. Proc Inst Mech Eng B 0954405416654419. https://doi.org/10.1177/0954405416654419

Karajibani E, Hashemi R, Sedighi M (2017) Forming limit diagram of aluminum-copper two-layer sheets: numerical simulations and experimental verifications. Int J Adv Manuf Technol 90:2713–2722. https://doi.org/10.1007/s00170-016-9585-1

Choi S-H, Kim K-H, Oh KH, Lee DN (1997) Tensile deformation behavior of stainless steel clad aluminum bilayer sheet. Mater Sci Eng A 222:158–165. https://doi.org/10.1016/S0921-5093(96)10514-1

Jiang ZY, Tieu AK (2002) Elastic–plastic finite element method simulation of thin strip with tension in cold rolling. J Mater Process Technol 130–131:511–515. https://doi.org/10.1016/S0924-0136(02)01020-8

Jiang ZY, Tieu AK (2001) A simulation of three-dimensional metal rolling processes by rigid-plastic finite element method. J Mater Process Technol 112:144–151. https://doi.org/10.1016/S0924-0136(01)00572-6

Fereshteh-Saniee F, Pillinger I, Hartley P (2004) Friction modelling for the physical simulation of the bulk metal forming processes. J Mater Process Technol 153:151–156. https://doi.org/10.1016/j.jmatprotec.2004.04.217

Liu J-G, Xue W (2013) Formability of AA5052/polyethylene/AA5052 sandwich sheets. Trans Nonferrous Metals Soc China 23:964–969. https://doi.org/10.1016/S1003-6326(13)62553-4

Luo L, Wei D, Wang X, Zhou C, Huang Q, Xu J, Wu D, Jiang Z (2017) Effects of hydraulic pressure on wrinkling and earing in micro hydro deep drawing of SUS304 circular cups. Int J Adv Manuf Technol 90:189–197. https://doi.org/10.1007/s00170-016-9380-z

Acknowledgments

The authors wish to acknowledge the financial support from Baosteel-Australia Joint Research and Development Centre (BAJC) under project of BA-16009. The first author is greatly thankful for the scholarship support (IPTA) from the University of Wollongong and scholarship support from the China Scholarship Council (CSC). The authors wish to gratefully acknowledge the help of Dr. Madeleine Strong Cincotta in the final language editing of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Z., Zhao, J., Jia, F. et al. Numerical and experimental investigation on the forming behaviour of stainless/carbon steel bimetal composite. Int J Adv Manuf Technol 101, 1075–1083 (2019). https://doi.org/10.1007/s00170-018-2985-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2985-7