Abstract

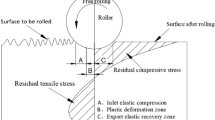

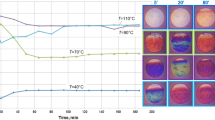

Physical parameters, such as microscopic and roughness, play important roles in microforming process due to an increasing ratio of surface to volume of the deformed material. The study on lubrication characterisation in microforming is getting more attractive to researchers because traditional models are not reliable in this scaled down process. In this study, the micro rolling deformation characterisation has been investigated on SUS 304 stainless steel considering lubricant effect and feature size effect. The foil thickness plays an important role in the tribological features of micro rolling. The evolutions of both oil film thickness and foil surface are analysed accordingly. All the results have been verified experimentally via the new developed 2-Hi desktop micro rolling mills.

Similar content being viewed by others

References

Le H, Sutcliffe M (2006) A multi-scale model for friction in cold rolling of aluminium alloy. Tribol Lett 22(1):95–104

Le H, Sutcliffe M (2003) A friction model for cold strip rolling with two-wavelength surface roughness in the “mixed” lubrication regime. Trans ASME 125(7):670–677

Lenard J, editor (2007) Primer on flat rolling, A monograph for those who need to understand the basic of the flat rolling process, Elsevier, 84 Theobald’s Road, London WC1X8RR, UK

Fleek N, Johnson K (1987) Towards a new theory of cold rolling thin foil. Int J Mech Sci 29(7):507–524

Fleek NA, Johnson KL, Mear ME, Zhang LC (1992) Cold rolling of foil. Porceedings Inst Mech Eng 26:119–131

Vollertsen F, Hu Z (2009) Tribological size effects in sheet metal forming measured by strip drawing test, Ann. CIRP 55:291–294

Deng J, Fu M, Chan W (2001) Size effect on material surface deformation behaviour in micro-forming process. Dep Mech Eng 528(13):4799–4806

Azushima A, Noro K (1998) Analysis and quantitative consideration of inlet oil film thickness in cold sheet rolling with oil in wateremulsions. J - Japn Soc Technol Plast 39:1238–1242

Sadowski P, Stupkiewicz S (2010) Combined effect of friction and macroscopic deformation on asperity flattening. Tribol Int 43(9):1735–1741

Dick K, Lenard J (2005) The effect of roll roughness and lubricant viscosity on the loads on the mill during cold rolling of steel strips. J Mater Process Technol 168(1):16–24

Batalha G, Filho M (2001) Quantitative characterization of the surface topography of cold rolled sheets—new approaches and possibilities. J Mater Process Technol 113(5):732–738

Wilson W, Walowit J (1972) An isothermal hydrodynamic lubrication theory for strip rolling with front and back tension, in: Proceedings of the Tribology Convention, I. Mech. E. London, 169-172

Lugt P, Wemekamp A, Napel W, Liempt P, Otten J (1993) Lubrication in cold rolling: elasto-plasto-hydrodynamic lubrication of smooth surfaces. Wear 166(3):203–214

Atkins AG (1974) Hydrodynamic lubrication in cold rolling. Int J Mech Sci 16:1–19

Kosasih PB, Tieu AK (2007) Mixed film lubrication of strip rolling using O/W emulsions. Tribol Int 40:709–716

Parit N, Cheng HS (1978) An average flow model for determining eggects of three-dimensinal roughness on parial hydrodynamic lubrication. ASME J Lubr Technol 100:12–17

Le HR, Sutcliffe MPF (2000) Analysis of surface roughness of cold-rolled aluninium foil. Wear 71-78

Sutcliffe MPF, Montmitonnet P (2001) Numerical modelling of lubricated foil rolling, La Revue de Metallurgie-CIT/Sciecnce et Genie des Materiaux. 435-442

Chang DF, Marsault N, Wilson WRD (1996) Lubrication of strip rolling in the low-speed mixed regime. Tribol Trans 39:407–415

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

**e, H., Manabe, Ki., Furushima, T. et al. Lubrication characterisation analysis of stainless steel foil during micro rolling. Int J Adv Manuf Technol 82, 65–73 (2016). https://doi.org/10.1007/s00170-015-7344-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7344-3