Abstract

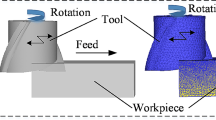

BTi-6431S is a promising material for aero-engine and supersonic speed aircraft parts application. However, the machinability of the alloy is relatively poor due to its high mechanical properties at high temperature. Laser-assisted machining (LAM) is a promising solution to reduce the cutting pressures when machining difficult-to-cut materials, such as Ti-6Al-4V alloy. In this paper, the machinability of this near-alpha alloy has been investigated in terms of cutting force, chip formation, and tool wear in different laser power conditions over a range of cutting parameters. This investigation shows that the BTi-6431S alloy is considerably less responsive to LAM compared to Ti-6Al-4V, and the tool life was not extended by using the LAM process for BTi-6431S. The main tool failure mode is flank wear and rake face chip** under conventional machining (CM) condition, while the diffusion wear is the main tool failure mode under LAM. The machinability of BTi-6431S near-alpha titanium alloy is significantly lower than that of Ti-6Al-4V alloy.

Similar content being viewed by others

References

Ezugwu EO, Wang ZM (1997) Titanium alloys and their machinability—a review. J Mater Process Technol 68:262–274

Machado AR, Wallbank J (1990) Machining of titanium and its alloys—a review. Proc Inst Mech Eng 204:53–60

Ezugwu EO (2005) Key improvements in the machining of difficult-to-cut aerospace superalloys. Int J Mach Tool Manuf 45:1353–1367

Arrazola PJ, Garay A, Iriarte LM, Armendia M, Marya S, Maitre FL (2009) Machinability of titanium alloys (Ti6Al4 V and Ti555.3). J Mater Process Technol 209:2223–2230

Naka S (1996) Advanced titanium—based alloys. Curr Opin Solid State Mater Sci 1(3):333–339

Veiga C, Davim JP, Loureiro AJR (2012) Properties and applications of titanium alloys: a brief review. Rev Adv Mater Sci 32:133–148

E.W.Collings. The physical metallurgy of titanium alloys. American Society for Metals (1984).

Peters M, Kumpfert J, Ward CH, Leyens C (2003) Titanium alloys for aerospace applications. Adv Eng Mater 5(6):419–427

X.Q.Wang, W.Q.Wang, H.H.MA. Microstructure and mechanical properties of high temperature and high strength BTi-6431S alloy at 700 °C. The Chinese Journal of Nonferrous Metals, 20 (2010) s792-s795.

Sun S, Harris J, Brandt M (2008) Parametric investigation of laser-assisted machining of commercial pure titanium. Adv Eng Mater 10(6):565–572

Sun S, Brandt M, Dargush MS (2010) The effect of a laser beam on chip formation during machining of Ti6Al4V alloy. Metall Mater Trans A 41A:1573–1581

S. Sun, M. Brandt, M. Dargusch. Effect of laser beam on the chip formation in machining of titanium alloys. ICALEO-27th International Congress on Applications of Lasers and Electro-Optics. Temecula, CA. (2008) 901–09

Dandekar CR, Shin YC, Barnes J (2010) Machinability improvement of titanium alloy (Ti-6Al-4V) via LAM and hybrid machining. Int J Mach Tool Manuf 50:174–182

Sun S, Brandt M, Banes JE, Dargusch M (2011) Experimental investigation of cutting forces and tool wear during laser-assisted milling of Ti-6Al-4V-alloy. Proc. IMechE, PartB. J Eng Manufacture 225:1512–1527

Bermingham MJ, Palanisamy S, Dargush MS (2012) Understanding the tool wear mechanism during thermally assisted machining Ti-6Al-4V. Int J Mach Tools Manuf 62:76–87

Rahman Rashid RA, Bermingham MJ, Sun S, Wang G, Dargush MS (2013) The response of the high strength Ti-10 V-2Fe-3Al beta titanium alloy to laser assisted machining. Precis Eng 37:461–472

Rahman Rashid RA, Sun S, Wang G, Dargush MS (2012) An investigation of cutting forces and cutting temperatures during laser-assisted machining of the Ti-6Cr-5Mo-5 V-4Al beta titanium alloy. Int J Mach Tools Manuf 63:58–69

Bermingham MJ, Schaffarzyk P, Palanisamy S, Dargusch MS (2014) Laser-assisted milling strategies with different cutting tool paths. Int J Adv Manuf Technol 74:1487–1494

Bermingham MJ, Sim WM, Gardiner S, Dargusch MS (2015) Tool life and wear mechanisms in laser assisted milling Ti-6Al-4V. Wear 322–323:151–163

A.K.Mathew. Prediction of the wear & evolution of cutting tools in a carbide/Ti-6Al-4V machining tribosystem by volumetric tool wear characterization & modeling. Doctor dissertation, Clemson University, (2012)

P.J.Arrazola, F.Meslin, S.Marya. Serrated chip prediction in numerical cutting models. In:Proceedings of the CIRP Congress 8 WMMO. 2005, 115–122.

Lacalle LNLD, Perez J, Llorente JI, Sanchez JA (2000) Advanced cutting conditions for the milling of aeronautical alloys. J Mater Process Technol 100(1–3):1–11

Hartung PD, Kramer BM (1982) Tool wear in titanium machining. Ann CIRP 31(January):75–80

Deng JX, Li YS, Song WL (2008) Diffusion wear in dry cutting of Ti–6Al–4V with WC/Co carbide tools. Wear 265:1776–1783

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, Y., Wang, G., Bermingham, M.J. et al. Cutting force, chip formation, and tool wear during the laser-assisted machining a near-alpha titanium alloy BTi-6431S. Int J Adv Manuf Technol 79, 1949–1960 (2015). https://doi.org/10.1007/s00170-015-6917-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6917-5