Abstract

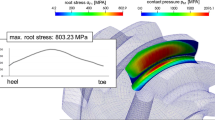

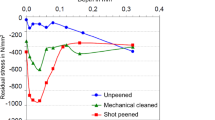

The manufacture of gears by applying hot or cold bulk forming processes is a quite widespread production method due to its well-known basic advantages such as material and time cost reduction and the increased strength of the teeth. However, the associated process planning and tool design are more complicated. In the precision forging of gears, the workpiece volume, the die design, the power requirement and careful processing are more critical than traditional forging technology. For complete filling up, predicting the power requirement is an important feature of the near net-shape forging process. In this paper, a finite element analysis is utilized to investigate the material properties such as yielding stress, strength coefficient and strain hardening exponent effects on forming load and maximum effective stress. The adductive network was then applied to synthesize the data set obtained from the numerical simulation. The predicted results of the maximum forging load and maximum equivalent stress of bevel gear forging from the prediction model are consistent with the results obtained from FEM simulation quite well. After employing the prediction model one can provide valuable references in prediction of the maximum forging load and maximum equivalent stress of bevel gear forging under a suitable range of material parameters.

Similar content being viewed by others

References

M. Meidert, M. Knoerr, K. Westphal and T. Altan. Numerical and physical modeling of cold forging of bevel gears,J. Mater. Proc. Technol. 33 (1992) 75–93.

A.G. Mamalis, D.E. Manolakos, A.K. Baldoukas. Simulation of the precision forging of bevel gears using implicit and explicit FE techniques.J. Mater. Proc. Technol. 51 (1996) 164–171.

T. S. Yang, A Finite Element Analysis for the Forging of Spur Gears,Journal of Chinese Society of Mechanical Engineers. 26 (2005) 547–552.

J. Choi, H. Y. Cho, C. Y. Jo, An Upper-bound analysis for the forging of spur gears,J. Mater. Proc. Technol. 104 (2000) 67–73.

F. C. Lin and C. T. Kwan, Application of abductive network and FEM to predict an acceptable product on T-shape tube hydroforming process,Computers and Structures. 82 (2004) 1189–1200.

T. S. Yang and Y. C. Hsu, Application of abductive network and FEM to predict the maximum forging force and the final face width of spur gear,Journal of Material Science Forum. 532–533 (2006) 861–864.

S. Kobayashi, S. I. Oh, T. Altan, Metal Forming and Finite-Element Method, Oxford University Press, Oxford, (1989).

DEFORM-3D User’s Manual, Version 5.1, Scientific Forming Technologies Corporation, Columbus, OH, (2003).

A. G. Ivakhnenko, Polynomial theory of complex system,IEEE Trans. Syst. 1 (1971) 364–378.

A. Patrikar, and J. Provence, Nonlinear system identification and adaptive control using polynomial networks,Math. Comput. Modeling. 23 (1996) 159–173.

A. R. Barron, Predicted square error: a criterion for automatic model selection, In: S. J. Farlow (Ed.), Self-organizing Methods in Modeling: GMDH Type Algorithms, Marcel-Dekker, New York (1984).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, T.S., Hwang, N.C. & Chang, S.Y. The prediction of maximum forging load and effective stress for different material of bevel gear forging. J Mech Sci Technol 21, 1566–1572 (2007). https://doi.org/10.1007/BF03177376

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF03177376