Abstract

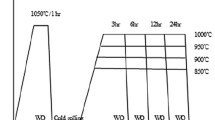

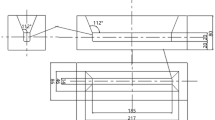

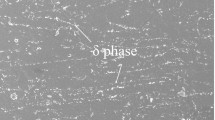

The 8 phase precipitation behavior of cold drawn alloy 718 has been investigated at 1116 K as a function of cold drawn ratio and aging time. The planar markings formed by cold drawing were identified as deformation twins and developed more clearly as cold drawing ratio increases. The grain boundaries and twins were played as nucleation site of δ precipitation, therefore, cold drawing enhanced the precipitation of δ particles. As the cold drawing ratio and aging time increased the amount of round-shaped δ also increased. In a specimen which was 50% cold drawn and aged for 4 hrs. the finely dispersed δ phase precipitated throughout the material. As aging time increased. The round-shaped δ phase changed to plate-like morphology, and the morphology transformation time was increased with cold drawing ratio. With a 50% cold drawn specimen, the transformation time was 7 hrs. On the other hand, for the 50% cold drawn specimen aged for one hour at 1116 K, nucleation of the strain free grain was observed.

Similar content being viewed by others

References

J. F. Barker, D. D. Krueger and D. R. Chang,Thermomechanical Processing of Inconel 718 and Its effect on Properties in “AdvancedHigh-temperature Alloys” (eds., S. M. Allen,et al.), p. 125, ASM (1985).

J. M. Oblak, D. S. Duvall and D. F. Paulonis,Metall Trans. 5, 143 (1974).

M. C. Chaturvedi and Ya-Fang-Han,Metal Sci. 17, 145 (1983).

H. C. Hall,J. Basic, Engng. 89, 511 (1967).

H. F. Merik,Met. Trans. 7A 506 (1976).

George E. Dieter,Mechanical Metallurgy, McGraw-Hill, p. 135 (1976).

N. A. Wilkinson, Forging of 718, The Importance of T. M. P., Superalloy 718, Metallurgy and Applications,The Minerals, Metals and Materials Society (ed., E. A. Loria), p. 119 (1989).

R. P. Singh, J. M. Hyzak, T. E. Howson and R. R. Biederman, Recrystallization Behavior of Cold Rolled Alloy 718,The Minerals, Metals and Materials Society (ed., E. A. Loria), p. 205 (1991).

G. Q. Zhang, R. W. Zhang and M. G. Yan, Investigation on the Strengthening of Inconel 718 Superalloy by Thermal Mechanical Treatments,Technical Report for Institute of Aeronautical Materials, p. 5, Bei**g, China (1988).

R. P. Singh, Ph. D. Thesis, Drexel University, Philadelphia, PA (1987).

M. Sundararaman, P. Mukhopadhyay and S. Banerjee,Acta. metall. 36, 847 (1988).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jeong, YK., Jo, CY., Kim, YH. et al. Effects of cold drawing ratio on δ phase precipitation behaviors of alloy 718 wire. Metals and Materials 3, 224–229 (1997). https://doi.org/10.1007/BF03025928

Issue Date:

DOI: https://doi.org/10.1007/BF03025928