Abstract

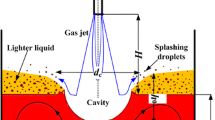

To detect the cavities formed behind the impeller blades, the electrical resistivity tech-nique was employed in this study. The transition conditions between large cavity and clinging cavity were easily detected by the proposed method and the reliabilty of the probe was confirmed by the comparison with literature. The characterististics of the cavities were observed as a function of impeller rotational speed and air flow rate. As the air flow rates increase, the type of cavities are changed from clinging cavities to large cavities. Large cavities were not observed in behind the impeller blades at high impeller speeds. In the region of the formation of alternate large and clinging cavities, the shapes of cavities were not changed and the positions of cavities were rarely shifted to other positions.

Similar content being viewed by others

Abbreviations

- D:

-

impeller diameter [mm]

- N:

-

impeller rotational speed [rps]

- NFl :

-

gas flow number (Q/ND) [-]

- NFr :

-

Froude number (ND/g) [-]

- NRe :

-

Reynolds number (ρND2μ) [-]

- Q:

-

gas flow rate [m3/s]

- T:

-

tank diameter [mm]

- ΔtB :

-

time duration which each blade passes by the tip of probe [s]

- Δtc :

-

time duration which signal is detected [s]

- ΔtMAX :

-

time duration which maximum voltage is maintained [s]

- ΔVMAX :

-

maximum voltage change [volts]

References

Pandit, A.B. and Joshi, J. B.:Chem. Eng. Sci,38, 1189 (1983).

Stravs, A. A. and von Stockar, U.:Chem. Eng. Sci.,40. 1169 (1985).

Tatterson, G. B. and Morrison, G. L:AIChE J.,33, 1751 (1987).

Nienow, A. W., Chapman, C. M. and Middleton, J. C.: Proc. 2nd Europ. Conf. on Mixing, Fl-1 (1977).

Warmoeskerken, M. M. C. G., van Houwelingen, M.C., Frijlink, J.J. and Smith, J.M.:Chem. Eng. Res. Des.,62, 197 (1984).

Smith, J. M., van’t Riet, K.: Proc. 2nd Europ. Conf. on Mixing, F4-51 (1977).

Warmoeskerken, M. M. C. G., Feijen, J. and Smith, J.M.:IChemE Symp. Ser.,64, J1 (1981).

Nienow, A. W. and Wisdom, D. J.:Chem. Eng. Sci.,29, 1994 (1974).

van’t Riet, K. and Smith, J. M.:Chem. Eng. Sci.,30, 1093 (1975).

Warmoskerken, M. M. C. G. and Smith, J.M.: World Congress III of Chemical Engineering, Tokyo, 8k-201 (1986).

Bruijn, W., van’t Riet, K. and Smith, J. M.:Trans. Inst. Chem. Engrs.,52, 88 (1974).

Ismail, A. F., Nagase, Y. and Imon, J.:AIChE J.,30, 487 (1984).

van’t Riet, K., Boom, J. M. and Smith, J. M.:Trans. Inst. Chem. Eng.,54, 1124 (1976).

Warmoeskerken, M. M. C. G. and Smith, J. M.:Chem. Eng. Sci.,40, 2063 (1985).

Lu, W. M. and Ju, S.J.:Chem. Eng. Sci,44, 333 (1989).

Rennie, J. and Valentin, F. H. H.:Chem. Eng. Sci.,23, 663 (1968).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, HR., Huh, YJ., Choi, CS. et al. Cavity formation in turbine stirred gas-liquid dispersion system. Korean J. Chem. Eng. 9, 164–168 (1992). https://doi.org/10.1007/BF02705134

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02705134