Abstract

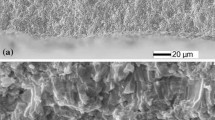

Zirconia stabilized with 20 wt.% yttria was deposited to a thick free-standing type, ∼7 mm, by (inductively coupled plasma spraying) (ICPS). The spheroidization of particles and the microstructure of deposits were analyzed. Spheroidization fraction dependence on spray parameters such as particle size, H2 gas mixing quantity, and probe position was studied. Effects of parameters on the spheroidization of particles were analyzed by ANOVA (analysis of variance) (ANOVA). ANOVA results showed that the spheroidization fraction largely depend on H2 gas mixing quantity and particle size, and there are also some dependence on probe position and H2 gas mixing quantity. After melting, particles kept their chemical composition homogeneously from the center to their surface without segregation or evaporation. The degree of deformation of the diameter of the splat over the diameter of the spheroidized particle was approximately 320%, and splat thickness in the deposit varies between 2 µm and 3 µm depending on the deposition condition. The yttrium concentration gradient of the interlayer boundary appeared linear in the range of 0.5 to 1 µm. X-ray diffraction analysis and a transmission electron microscope (TEM) micrograph showed that low yttrium content particles resulted in tetragonal phase in deposit. The major characteristics of the microstructure of the thick free-standing deposit and solidification mode were studied. Microstructure of the bottom part of the deposit represented equiaxed or cellular structure. Equiaxed small grains prevailed when the droplets were quenched rapidly on substrate. The middle part of the deposit showed large columnar grains, of about 100 µm thick and 300 µm long. This may be due to high substrate or deposit temperatures and results in recrystallization and grain growth.

The effects of the parameters, such as H2 gas mixing quantity, particle size, spraying distance, and probe position, on the microstructure of the deposits were evaluated. The H2 gas mixing quantity of Ar/H2=120/20 L/min compared to Ar/H2=120/10 L/min resulted in larger grain size and thicker cellular in chill. Grain shapes were affected by the heat removal rate from the deposit to its surrounding. Deposition with larger particle size showed heterogeneous grain size, insufficient particle melting, and incomplete recrystallization. The effect of probe position was less than the others.

Similar content being viewed by others

References

L. Pawlowski:The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, New York, NY, 1995, p. xv.

S. Sampath, R.A. Neiser, H. Herman, J.P. Kirkland, and W.T. Elam:J. Mater. Res., 1993, vol. 8 (1), pp. 78–86.

E. Pfender:Plasma Chem. Plasma Proc., 1999, vol. 19 (1), pp. 1–31.

S. Sampath, X.Y. Jiang, J. Matejicek, A.C. Leger, and A. Vardelle:Mater. Sci. Eng., 1999, vol. A272, pp. 181–88.

S. Sampath:Mater. Sci. Eng., 1993, vol. A167, pp. 1–10.

J. Jurewicz, R. Kaczmarek, and M.I. Boulos:Radiofrequency Induction Plasma Deposition of Metals and Alloys under Reduced Pressure, ICPS-7, ICPS, Eindhoven, Netherlands, 1985, pp. 1131–36.

X. Fan: Ph.D. Thesis, University of Sherbrooke, Sherbrooke, PQ, Canada, 1994.

X.L. Jiang: Ph.D. Thesis, University of Sherbrooke, Sherbrooke, PQ, Canada, 1994.

H.J. Matzke, V.V. Rondinella, and T. Wiss:J. Nucl. Mater., 1999, vol. 274, pp. 47–53.

K.K. Srivastava, R.V. Patil, C.B. Choudhary, K.V.G.K. Gokhale, and E.C. Subbarao:Trans. J. Br. Ceram. Soc., 1974, vol. 73 (3), pp. 85–91.

E.M. Levin, C.R. Robbins, and H.F. McMurdie:Phase Diagrams for Ceramists, American Ceramic Society, Columbus, OH, 1964, pp. 107, 141–42, and 163.

A. Vardelle, M. Vardelle, and P. Fauchais:Plasma Chem. Plasma Proc., 1982, vol. 2 (3), pp. 255.

H. Herman:MRS Bull., 1988, Dec., pp. 60–67.

X. Fan, F. Gitzhofer, and M.I. Boulos:J. Thermal Spray Technol., 1998, vol. 7 (2), pp. 247–53.

R. Kingswell, K.T. Scott, and L.L. Wassell: inThermal Spray: International Advances in Coatings Technology, C.C. Berndt, ed., ASM International, Materials Park, OH, 1992, p 421–26.

T.C. Nerz, J.E. Nerz, B.A. Kushner, A.J. Rotolico, and W.L. Riggs: inThermal Spray: International Advances in Coatings Technology, C.C. Berndt, ed., ASM International, Materials Park, OH, 1992. pp. 405–13.

D.J. Varacalle, Jr., E. Acosta, J. Figert, M. Syma, J. Worthington, and D. Carrillo: inThermal Spray: Practical Solutions for Engineering Problems, C.C. Berndt, ed., ASM International, Materials Park, OH, 1996, pp. 699–707.

D.C. Montgomery:Design and Analysis of Experiments, 4th ed., John Wiley & Sons, New York, NY, 1997, pp. 290–341.

P. Scardi and L. Lutterotti:Surface Coating Technol., 1993, vol. 61, pp. 52–59.

C.A. Anderson, J. Greggi, Jr., and T.K. Gupta: inScience and Technology of Zirconia II: Advanced in Ceramics, N. Claussen, M. Ruhle, and H. Heuer, eds., The American Ceramic Society, Columbus, OH, 1983, vol. 12, pp. 80.

S. Sampath and H. Herman:12th Int. Thermal Spraying Conf., London, June 4–9, 1989, paper no. 53.

C. Moreau, P. Cielo, M. Lamontagne, S. Dallaire, J.C. Krapez, and M. Vardelle:Surface Coating Technol., 1991, vol. 46, pp. 173–87.

L. Pawlowski:The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, New York, NY, 1995, pp. 122–27.

C. Moreau, P. Cielo, and M. Lamontagne: inThermal Spray: International Advances in Coatings Technology, C.C. Berndt, ed.,ASM International, Materials Park, OH, 1992, pp. 761–66.

H. Bhat and H. Herman:Thin Solid Films, 1982, vol. 95, pp. 227–35.

W. Kurz and D.J. Fisher:Solidification, Trans Tech Publications, Aedermannsdorf, Netherlands, 1984, pp. 28–34.

F.J. Esper, K.H. Friese, and H. Geier: inScience and Technology of Zirconia II: Advanced in Ceramics, N. Claussen, M. Ruhle, and H. Heuer, eds., The American Ceramic Society, Columbus, OH, 1983, vol. 12, pp. 533.

L. Pawlowski:The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, New York, NY, 1995, pp. 139–46.

L. Pawlowski:The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, New York, NY, 1995, p. 160.

L. Pawlowski:The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, New York, NY, 1995, p. 128.

W.D. Kingery, H.K. Bowen, and D.R. Uhlmann:Introduction to Ceramics, 2nd ed., Wiley, New York, NY, 1976, p. 526.

L. Pawlowski:The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, New York, NY, 1995, p. 449.

Y.W. Kim, D.L. Bourell, and C. Persad:Mater. Sci. Eng., 1990, vol. A123, pp. 99–115.

A.J.F. Craig and M. Hideaki:Comput. Mater. Sci., 1999, vol. 14, pp. 177–84.

A.R. Nicoll and H. Eschnauer:Proc. 11th Int. Thermal Spray Conf., Montreal. Sept. 8–12, 1986, pp. 289-99.

I.H. Jung, K.K. Bae, M.S. Yang, and S.K. Ihm:Proc. 1999 US-Korea Materials Conf (UKC), Los Angeles, CA. Aug. 12–14, 1999.

M.I. Boulos, P. Fauchais, and E. Pfender:Thermal Plasmas: Vol. 1, Plenum Press, Elmsford, NY, 1994, p. 251.

L. Pawlowski:The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, New York, NY, 1995, p. 21.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jung, IH., Bae, KK., Yang, MS. et al. A study of the microstructure of yttria-stabilized zirconia deposited by inductively coupled plasma spraying. J Therm Spray Tech 9, 463–477 (2000). https://doi.org/10.1007/BF02608548

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02608548