Conclusions

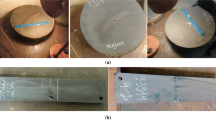

SP-13-1 stoppers made from Chasov-Yar clay by the plastic method with a porosity of 18 or 19% are not insufficiently spalling resistant.

When using stoppers with a porosity of 19–24%. the breakage of the spherical part of the stoppers during service ceased and the number of faulty pourings was sharply reduced.

An increase of the spalling resistance and porosity of the stoppers can be brought about by reducing the firing temperature or increasing the chamotte content in the charge to 65%.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zima', V.K., Jhukova, E.I. & Koval'Chuk, Y.I. Improvement of operation properties of stoppers for casting steel from large-capacity ladles. Refractories 2, 384–385 (1961). https://doi.org/10.1007/BF01326491

Issue Date:

DOI: https://doi.org/10.1007/BF01326491