Conclusions

As a result of investigations into newly developed refractories and a study of their service conditions in the stoves of blast furnaces, three basic types of failure in the structure and the checkers were determined:the formation of vertical cracks in the dome and walls; deformation of the checkers and the upper part of the combustion chamber; and failure of the lower part of the combustion chamber. The formation of cracks can be eliminated by selecting the optimum joints, and by using a design in the stoves which takes into account the properties of the refractories under variable temperatures.

In order to reduce the deformation of the checkers and the combustion chamber it is recommended that these zones be made of refractories possessing the minimum creep, in the first case dinas with low embrittlement factors, and high-alumina products made of kaolin and calcined alumina.

The lower part of the combustion chamber should be built from high-alumina and kaolin refractories possessing a high resistance to thermal shock.

It is found that the upper rows of the checker become saturated with fusible compounds, formed when batch dust falls on the material, which means a substantial reduction in their thermal-mechanical properties, contributing to an increase in the deformation under load.

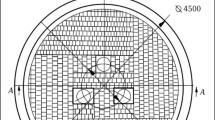

To increase the blast temperature to 1300–1400°C it is necessary to use, in the high-temperature zones, mullite, mullite-corundum refractories based on kaolin, and low-embrittlement dinas with the compulsory completion of a number of measures: installation of an emission combustion chamber, removal of the dome load from the working walls, the use of perforated checkers, the construction of a special device for putting the furnace on draft, purification of the gases and air to remove dust and fusible substances, a reduction in the heating period, and the organization of paired-parallel operation of the stoves.

Similar content being viewed by others

Literature cited

I. I. Korobov, Metallurgy i Gornorud. Prom., No. 5, 12 (1963).

L. Ya. Levin et al., Byull. TSIIN ChM, No. 20 (1961).

G. T. Brendi et al., Chernye Metally, No. 21, 3 (1966).

V. D. Tsigler and V. D. Bulakh, Metallurgy i Gornorud. Prom., No. 3, 47 (1968).

Klepzig Fachber, No. 1, 17 (1964).

G. Wecht, Ber. Dtsch. Keram. Ges.,43, No. 1, 106 (1966).

S. A. Zhikharevich et al., Ogneupory, No. 4, 8 (1966).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 1, pp. 23–32, January, 1972.

Rights and permissions

About this article

Cite this article

Pitak, N.V., Gin'yar, E.A. & Usatikov, I.F. Damage to stoves and measures to eliminate it. Refractories 13, 24–31 (1972). https://doi.org/10.1007/BF01287703

Issue Date:

DOI: https://doi.org/10.1007/BF01287703