Abstract

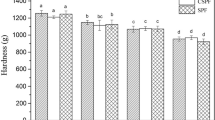

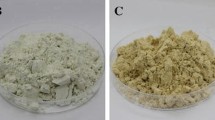

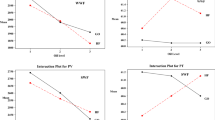

Dry heat treatments at 140 °C for 20 min or 160 °C for 10 min of peanut kernels significantly improved protein solubility, water and oil absorptions, foaming capacity and stability, and least gelation concentration of the defatted meal. However, heat treatments at 160 °C for 30 min or more than 30 min period resulted in significant decrease in these properties. Such heat treatments significantly decreased the level of albumin and globulin fraction with concomitant increase in glutelin fraction in the meal.

Similar content being viewed by others

References

Ahmed EM, Pattee HE (1987) Peanut Quality. Its Assurance and Maintenance from the Farm to End-Product. Bull. 874, Agric Exp Stn, University of Florida, Gainesville, Institute of Food and Agric. Sci., p. 10

Woodroof JG (ed) (1983) Peanuts: Production, Processing and Products, 3rd ed. Westport, Conn: Avi Publ. Co. Inc.

Damame SV, Chavan JK, Kadam SS (1990) Effects of roasting and storage on proteins and oil in peanut kernels. Plant Fds Hum Nutr 40: 143–148

Basha SM, Young CT (1985) Changes in polypeptide composition of peanut seed during oil roasting. J Agric Fd Chem 33: 350–354

McWatters KH, Cherry JP (1975) Functional properties of peanut paste as affected by moist heat treatment of full-fat peanuts. J Fd Sci 40: 1205–1209

Rahma EH, Mostafa MM (1988) Functional properties of peanut flour as affected by different heat treatments. J Fd Sci Technol 25: 11–15

Lowry OH, Rosenbrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin-Phenol reagent. J Biol Chem 193: 265–275

Nagy D, Weildein W, Hixon RW (1941) Factors affecting solubility of corn proteins. Cereal Chem 18: 514–518

AOAC (1975) Official Methods of Analysis, 12th ed. Washington, DC: Association of Official Analytical Chemists, pp. 15–16

Beuchat LR (1977) Functional and electrophoretic characteristics of succinylated peanut flour. J Agric Fd Chem 25: 258–261

Coffman CW, Garcia NV (1977) Functional properties and amino-acid content of protein isolate from mung bean flour. J Fd Technol 12: 473

Chiou RYY, Tsai TT (1989) Characterization of peanut proteins during roasting as affected by initial moisture content. J Agric Fd Chem 37: 1377–1381

McWatters KH, Cherry JP, Holmes MR (1976). Influence of suspension medium and pH on functional properties of defatted peanut meal. J Agric Fd Chem 24: 517–523

Cherry JP, McWatters KH, Holmes MR (1975) Effects of moist heat on solubility and structural components of peanut proteins. J Fd Sci 40: 1199–1204

Perkins D, Toledo RT (1982) Effect of heat treatment for trypsin inhibitor inactivity and functional properties of peanut proteins. J Fd Sci, 917–923.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Patil, U.G., Chavan, J.K., Kadam, S.S. et al. Effects of dry heat treatments to peanut kernels on the functional properties of the defatted meal. Plant Food Hum Nutr 43, 157–162 (1993). https://doi.org/10.1007/BF01087919

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01087919