Abstract

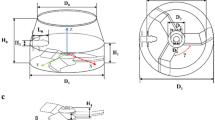

An experimental study is performed on a gas-particle stirred ladle system with throughflow, using a simplified water model. Narrow ladles are used to produce 2-D flows. Flow visualization by the direct photographic method is employed to investigate the effects of ladle geometry, throughflow rate, air flow rate and its injection location on the melt-particle mixing performance. Image processing is applied to aid in determining the mixing performance. It is disclosed that an efficient mixing may be achieved if the gas at a higher flow rate is injected with particles through a nozzle near the bottom corner of the ladle wall on the melt inlet side. The mixing performance is better in a rectangular ladle (aspect ratio of 2) than in a square ladle (aspect ratio of unity). The effect of throughflow rate on mixing is minor. The study has an important application in manufacturing processes, such as continuous casting process, and materials processing.

Similar content being viewed by others

Abbreviations

- AR :

-

aspect ratio

- B :

-

width of water vessel, m

- Bn :

-

Nozzle location on bottom surface of water vessel, m

- H :

-

height of water vessel or height between bottom surface and free surface of water vessel, m

- Hn :

-

Nozzle location on vertical (inlet side) surface of water vessel, m

- Q g :

-

volumetric rate of gas, m3/s

- Q l :

-

volumetric rate of water, m3/s

- Q s :

-

volumetric rate of particle, m3/s

- x :

-

transverse coordinate, m

- y :

-

longitudinal coordinate, m

References

Grevet, J. H.; Szekely, J.; El-Kaddah, N. 1982: An experimental and theoretical study of gas-bubble driven circulation systems. Int. J. Heat Mass Transf. 25, 487–497

Mazumdar, D.; Guthrie, R. I. L. 1985: Hydrodynamic modeling of some gas injection procedures in ladle metallurgy operations. Metall. Trans. B. 16B, 83–90

Sahai, Y.; Guthrie, R. I. L. 1986: Recent advances in the hydrodynamics of metallurgical processing. In: Advances in transport processes. (eds. Mazumdar, A. S.; Mashelakar, R. A.), pp. 1–48. New York: Halsted Press

Sahai, Y.; Guthrie, R. I. L. 1982a: Hydrodynamics of gas stirred melts: part I. gas/liquid coupling. Metall. Trans. B. 13B, 193–202

Sahai, Y.; Guthrie, R. I. L. 1982b: Hydrodynamics of gas stirred melts: part II. axisymmetric flows. Metall. Trans. B. 13 B, 203–211

Szekely, J.; Wang, H. J.; Kiser, K. M. 1976: Flow pattern velocity model of an argon-stirred ladle. Metall. Trans. B. 7 B, 287–295

Author information

Authors and Affiliations

Additional information

Visiting scholar on leave from the Mechanical Engineering Department, Kagoshima University, Japan

Rights and permissions

About this article

Cite this article

Torii, S., Yang, W.J. Melt-particle mixing in gas-stirred ladles with throughflow. Experiments in Fluids 13, 37–42 (1992). https://doi.org/10.1007/BF00208073

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00208073